The Tools of Your Trade - Aeronaut Automated Cutting Systems

For over 30 years, Aeronaut has been making the essential automated cutting systems, software and accessories to help you get your job done.

For technical and recreational textiles, upholstery and packaging, we've developed the cutters, tooling, software and accessories to make your work faster, easer, more profitable and more fun.

We've supported customers like you with reliable tools that work as hard as you do on the day to day tasks and for those out of the ordinary jobs, we've made the special machines.

Look around and see what our extraordinary customers are doing with Aeronaut cutting systems, from Mars lander parachutes and space suits to window blinds, cars seats, truck curtains and RVs.

Aeronaut Automated Cutting Systems

Modular Machines

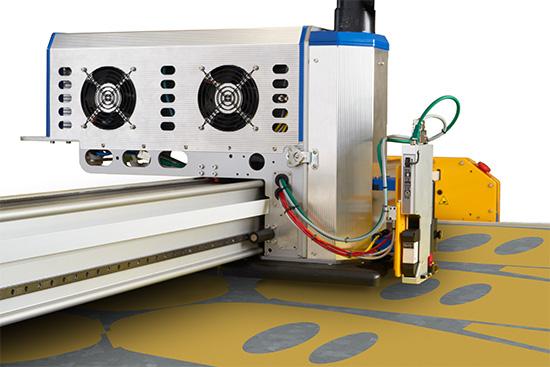

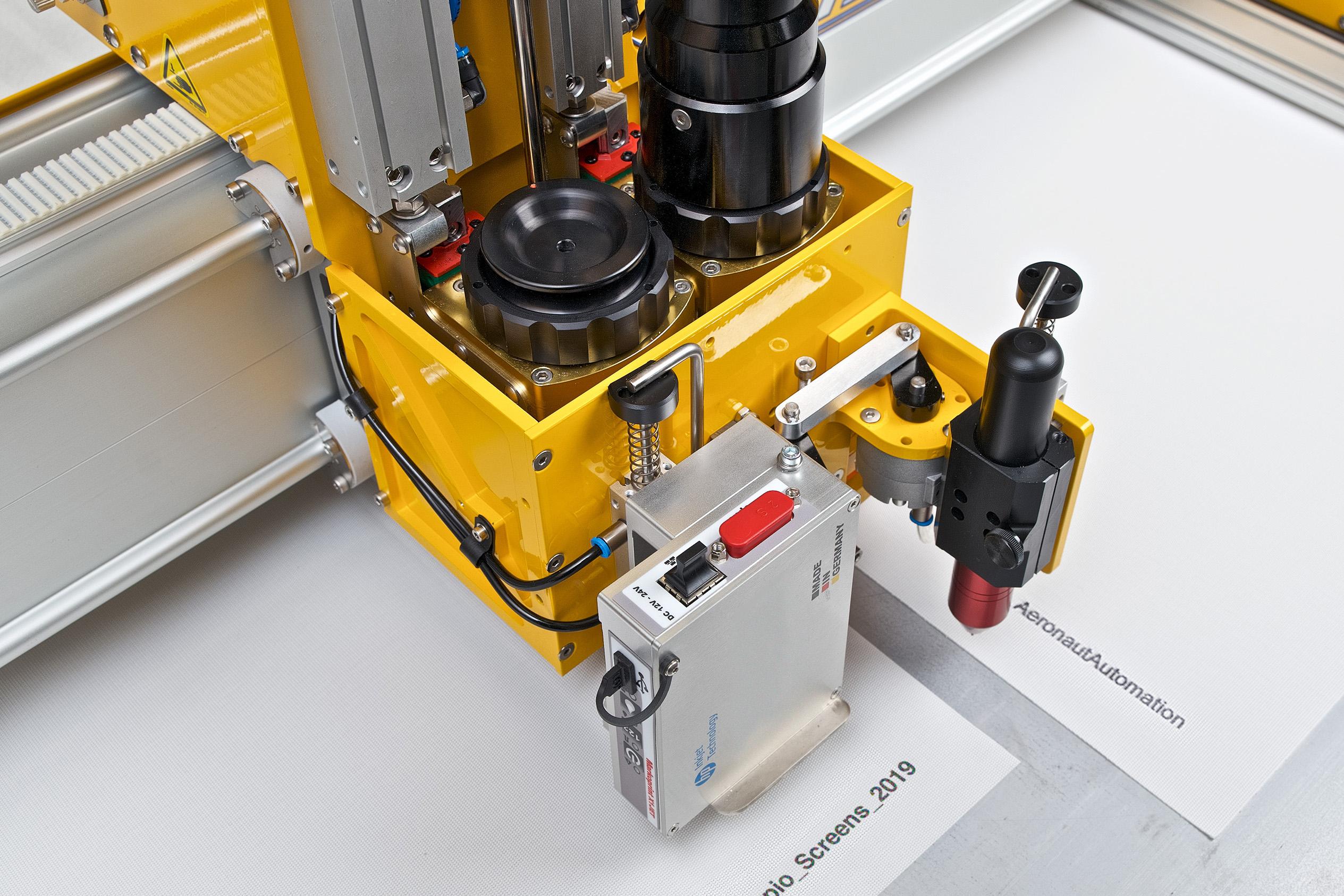

Aeronaut's machines are modular. We've developed a series of standard building blocks for cutting heads, quick-change tooling and accessories. Gantries are extrusion based as are our flat-pack cutting tables so they can be configured and fitted together, even as we admit, in a dizzying range of combinations.

These modules can be fitted together to create a highly versatile, future proof and expandable machine from 900mm (36") to 12,000mm (472")wide and over 50 metres (164') long. So if you have a special job and don't see the machine you need on these pages, just ask. Maybe we've made one already.

Aeronaut makes automatic cutters into cutting systems fitted with the widest range of cutting technologies.

Rotary blade, reciprocating blade, laser and ultrasonic in formats from the most versatile and future proof cutting systems on the market to simple and affordable entry-level self-installed machines and almost everything in between.

Aeronaut's cutters are notable for their rational engineering, uniquely efficient quick-change tooling, functional styling and incredibly long service life.

Look at the cutters menu for information about the cutters we make. Or you can look at the industries menu to get an idea about what type of cutter might suit a particular industry. Or just contact us by phone or email using the form below and talk to us about your own work.

Easy to Use

Simple to Maintain

High Reliability

Industries

Leather & Upholstery

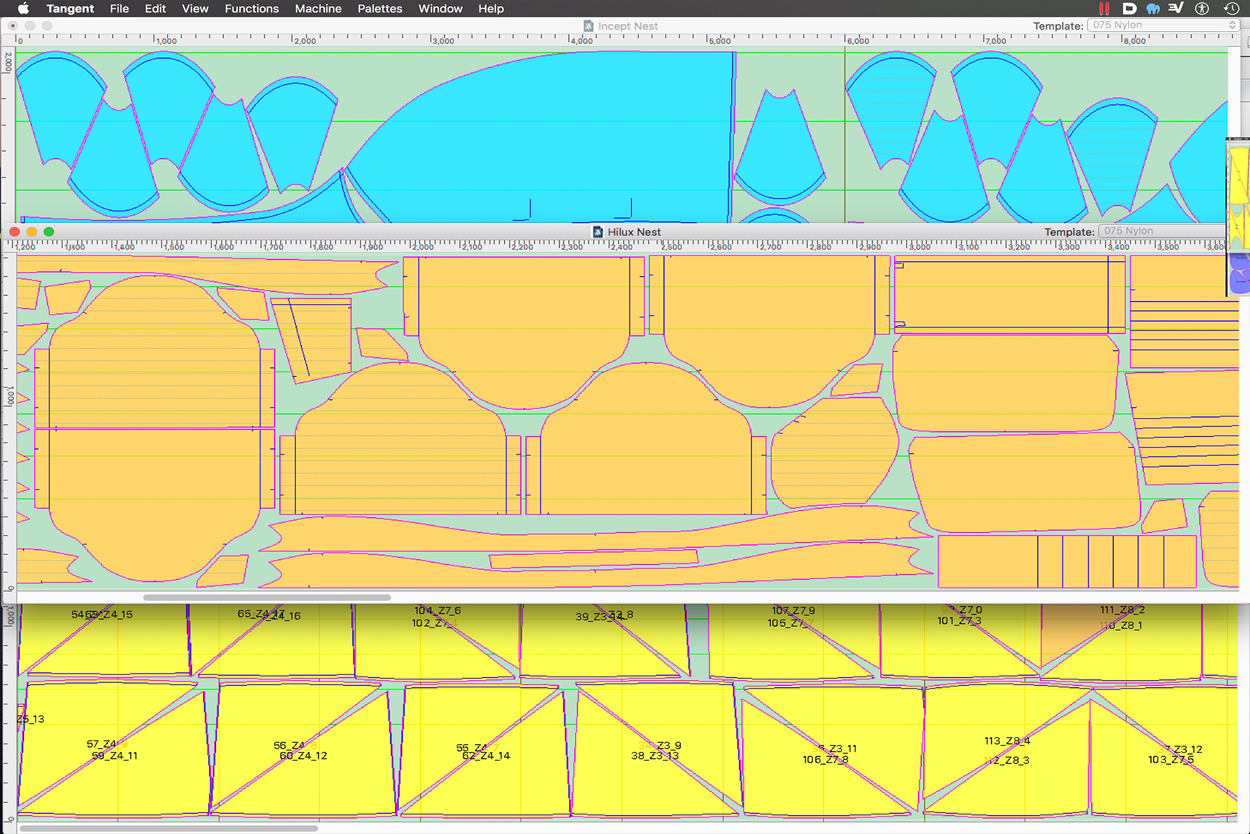

Aeronaut developed a low cost leather cutting system almost two decades ago and it's evolved into a very powerful system for cutting leather and upholstery products mainly due to Aeronaut's brilliant SiliconEye machine vision system for hide and pattern scanning and interactive nesting.

Increase Productivity

Reduce Waste

Reduce Mistakes

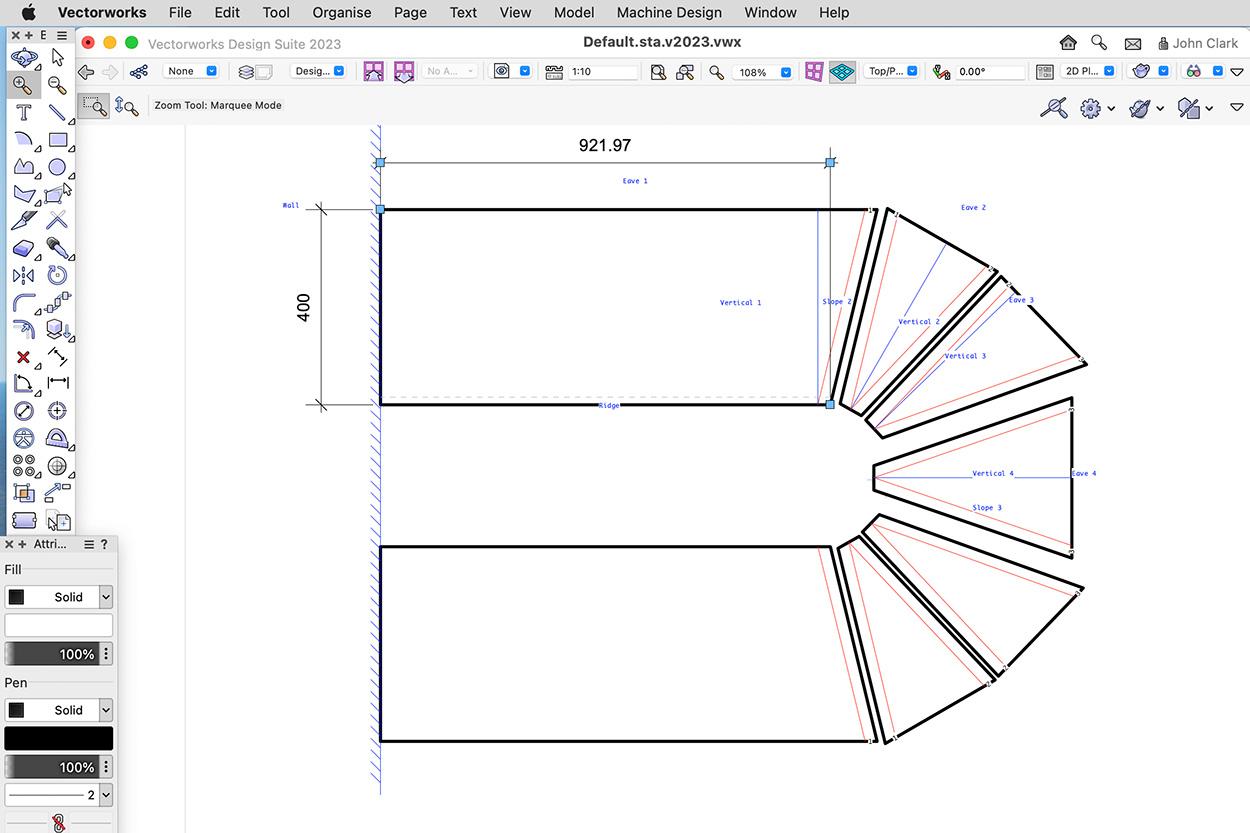

Software, Nesting and Technology

Why Automate?

Most of the benefits of automation are obvious, others less so.

- Automation will increase productivity without increasing staff numbers while at the same time reducing waste, mistakes and staff stress at busy times.

- If you don't want growth, automation can let you produce the same number of good quality products with fewer staff.

- Automation reduces your reliability on key workers and conventional skills while attracting another generation of workers who might be entirely happy with computers but less so pushing a pair of scissors.

- Automation adds value to a business since the IP, designs and patterns are all digitised and can be stored off-site.

- Cutting accurate patterns no longer depends on key workers. Aeronaut cutter are easy to operate so many people can run a cutter and saved jobs can be easily recut.

- Automation means you can do more markings and more markings means faster, more accurate and more reliable assembly. The cutting and marking process may take a while longer but the sewing, welding or bonding operations are much faster.

Why Aeronaut?

- Apart from the obvious reason that Aeronaut has some of the best people around in sales, design, software and support…

- Aeronaut cutters are legendarily reliable. We've got dozens of cutters over 20 years old which are still doing the same reliable job for their owners.

- The cost of ownership of an Aeronaut cutter is very low. Upgrades, spares and service are readily available even for 30 year old machines.

- Over a third of new machine orders are from customers who already own at least one Aeronaut cutter, something which applies across the board from NASA contractors to the boat cover maker down the road.

- Aeronaut's cutters are rationally designed machines. As one customer said, "if we'd bought another make of cutter, we'd have spent more on plastic covers than we did on our whole machine".

- Aeronaut cutters may be overbuilt, like a '70s Mercedes, but there's a sense of security in knowing that your 3 metre wide cutter is also working somewhere else at 6 metres wide.

- If it's yellow, it doesn't break! 90% of components are made in-house on one of 5 CNC machines, most of which are German 5 axis machining centres. If we made it once, we can make it again.

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!