SiliconEye Machine Vision System

Aeronaut's SiliconEye is a machine vision system which looks at your entire cutting table. In fact, SiliconEye is just a well calibrated digital SLR camera but what makes it into a machine vision system and sets it apart from other scanners and digitising software is how it works with Aeronaut's Tangent nesting software.

Not having SiliconEye over your cutting table, is like cutting with your eyes shut!

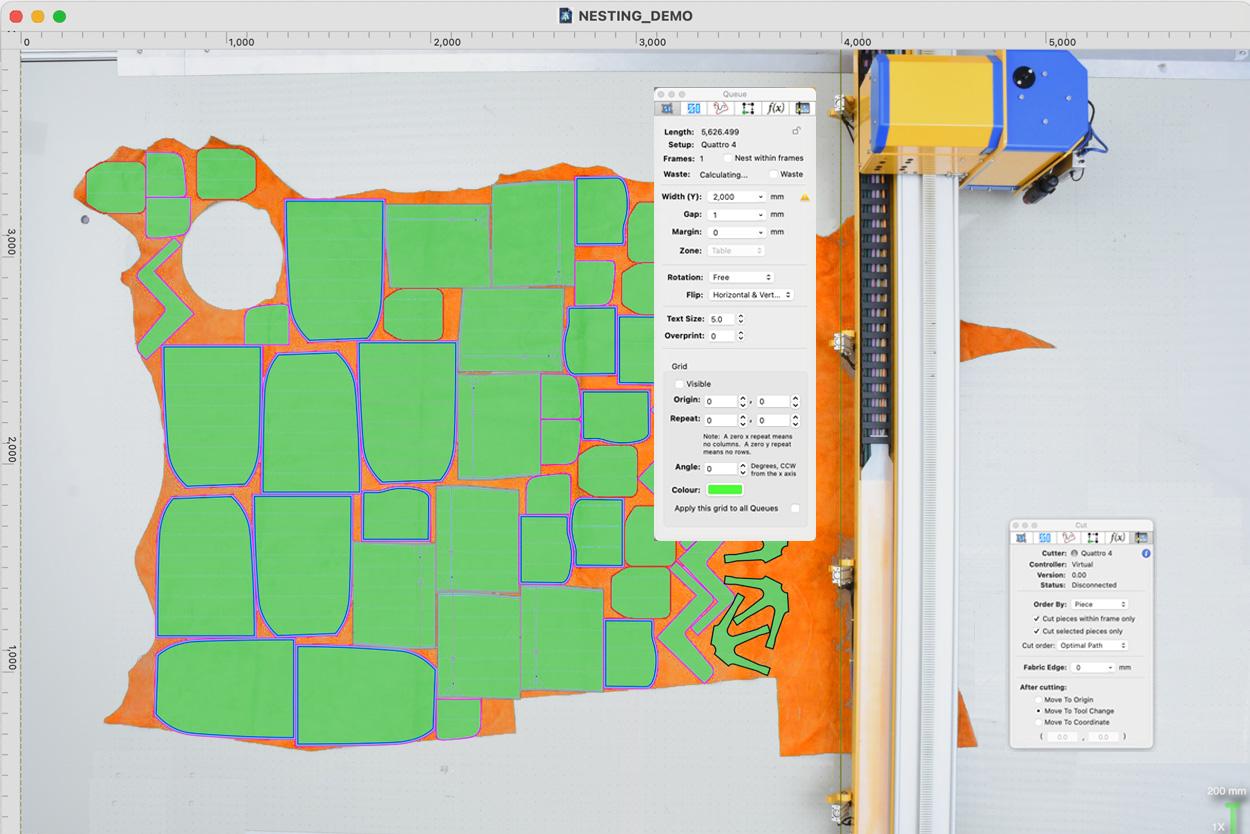

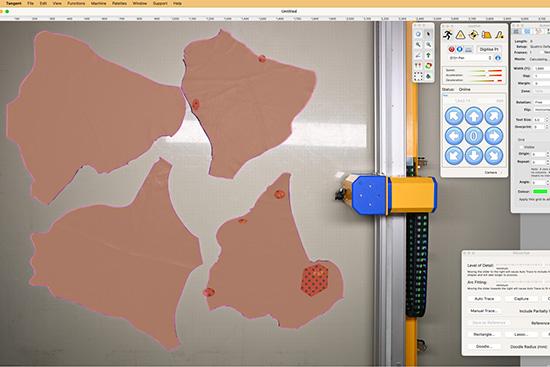

Tangent controls the camera. A picture is taken and downloaded into the background of the active queue. Tangent undistorts the image so it is calibrated to the cutting table. In most cases, you would not have the cutter in frame when you take the picture but we're showing it so you can get the idea.

The image is now locked to the nesting queue and at the simplest level, patterns can now be accurately positioned with the mouse over any fabric in the picture. But there's a lot more you can do.

If the fabric on the cutting table is an irregular size, scrap material for example, you can auto trace the fabric outline and nest within it.

If the fabric is patterned or has stripes, you can align marks on the pattern to the details on the fabric to make sure that it's a good match.

SiliconEye can trace patterns. A whole table full at a time if that's what you want. Tangent optimises the traces to remove excess points and noise to give you clean patterns which are often ready to cut. Circles and rectangles are cleaned up to match the original entity.

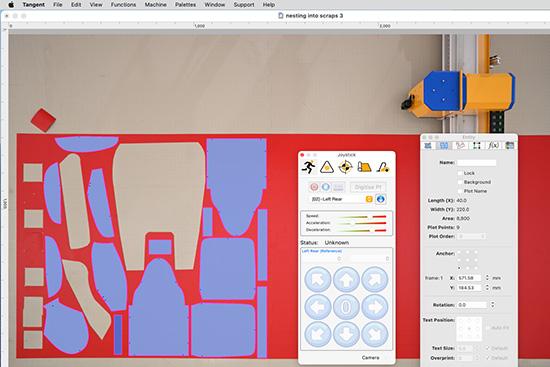

Nesting Into Scraps

Science has not yet discovered why people start to cut a pattern right in the middle of a piece of expensive fabric… but they do. SiliconEye allows you to reduce your material scrap by interactively placing patterns directly over the image of the fabric.

If you have stock cutting queues, then small patterns can be easily nested around cutouts and faults in fabric.

If you have Tangent with Autonest+, the queue can be traced and the cutouts nested around automatically.

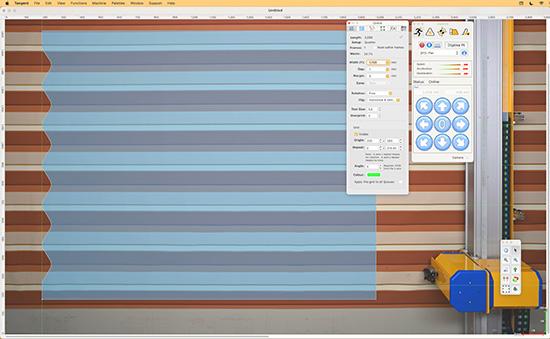

Matching Patterns

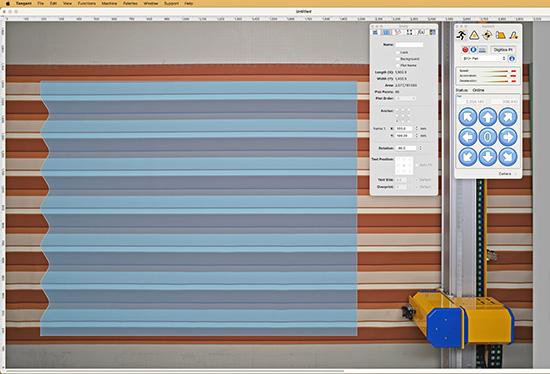

Pattern matching cut profiles to striped or patterned material is made a lot easier with SiliconEye over the cutting table.

Tangent has plenty of features like grids and alignment marks which can be used over the SiliconEye image to make sure the pattern match is the way you want.

There's no real need for the fabric to be straight down the table either since both the grid and cut profile can be incrementally rotated to match the actual fabric on the table.

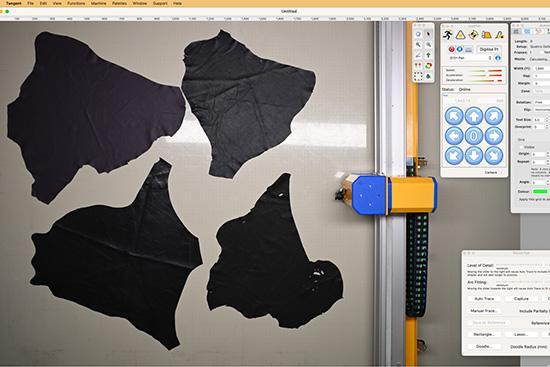

Tracing Shapes

SiliconEye can trace multiple shapes on the cutting table, whether they're templates, actual objects or something like leather hides or scraps of fabric.

SiliconEye's will autotracing captures everything, minimising bumps, noise and excess points to give you a vector profile which can be exported to CAD software or in many cases, cut straight away.

This is a huge time saver when you're working with traditional templates to prototype products.

Marking Fabric Faults

Fabric has faults. It's a fact of life. With SiliconEye, you can see fabric faults right where they lie on the table and with Tangent's Fault Line tool, mark them, whether they're a pulled thread, stain or a hole or scar on a hide.

You can zoom right into the nesting queue to look at faults and the texture of material to make sure key patterns avoid any problems.

Avoiding Fabric Faults

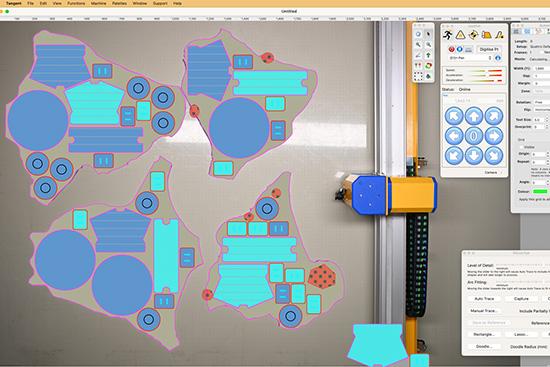

This queue of patterns shows two things; nesting into enclosed shapes and fault avoidance.

Any traced pattern on the cutting table can be marked as a background shape and other patterns autonested inside. Here, these 4 small hides have been made background patterns and automatically filled with cut profiles.

Because these hides had a few faults and holes marked with Fault Line, Tangent's Autonest+ feature has avoided the faults during the autonest process.

Nesting Patterns and Stripes

Pattern matching cut profiles to striped or patterned material is made a lot easier with SiliconEye over the cutting table.

Tangent has plenty of features like grids and alignment marks which can be used over the SiliconEye image to make sure the pattern match is the way you want.

There's no real need for the fabric to be straight down the table either since both the grid and cut profile can be incrementally rotated to match the actual fabric on the table.

SiliconEye Specifications

Setup

Cameras. The performance of SiliconEye depends on having a reasonably high resolution camera and wide angle lens. You cannot expect to use your own camera.

Resolution. At typical DSLR camera has a pixel count of 6000 x 4000 pixels. On a 2 metre wide table, that would mean about 2px per mm. Some resolution is lost through the undistorting process but an accuracy of about 2-3mm is possible on most tables.

For more demanding purposes, a higher resolution camera can be used at the cost of slightly longer capture times.

Performance

Mounts. Cameras can be fitted using the supplied mount to most ceilings, hung off walls or off floor mounted poles.

Ceiling Height. A high ceiling is best for a good picture but with modern wide angle lenses, a 2.4 metre (8') will let you cover a 2.4 metre wide cutting table.

Coverage. A single camera will cover most cutting table sizes but if the table is very large, then more than one camera can be used.

Capture time. On a modern computer and a USB-3 equipped camera, capture times are under 5 seconds from the shutter command to the image appearing in the queue.